SERVICES

SERVICES

Water-jet Cutting

You can cut from 5/128" to 6’' thick material

Is the waterjet for you ?

The ideal waterjet cutting system for large steel & aluminum plate Waterjet is the most versatile process, able to cut almost any type of steel or aluminum.

Waterjet is a very precise cutting process. It has a narrow kerf width, allowing fine contours to be cut, and producing high tolerance parts from any metals, including mild steel, stainless steel, and aluminum.

Plasma cutting

you can cut from 5/128” to 2.5” thick material

Need to save money and time?

Plasma can be used for cutting metals such as stainless steel, aluminium and copper, of varying thicknesses. It can cut both ferrous and nonferrous metals, but non-conductive materials such as wood or plastic cannot be cut with a plasma cutter. Plasma is faster than a water jet and a laser cutting systems for thickness over 3mm

Press Brake

Bend the thinnest material to 2”

Bending to save time and money

Our array of state-of-the-art press brakes are capable of handling simple to complex and light gauge to heavy plate custom and production forming

SERVICES

SERVICES

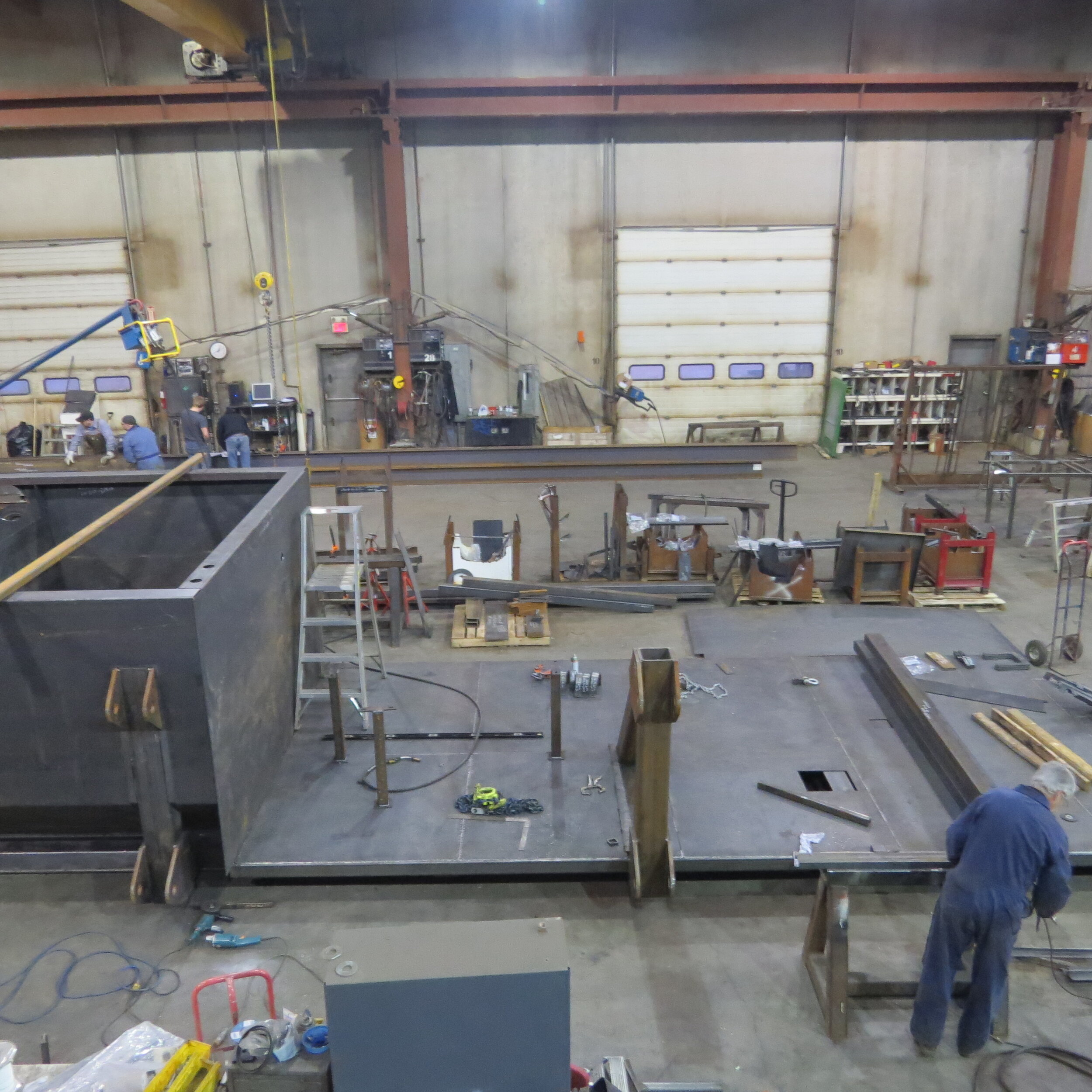

Welding Services

For well over 35 years, our business has been focused on offering welding, complete custom metal fabrication from concept, design and drafting to fabrication and finishing. Located in Linden, we offer mobile and in-shop welding and custom fabrication services. Our knowledgeable and experienced certified welders can build, modify or repair to your specifications. We specialize in steel, aluminum, stainless materials.

Shot-blasting

Speed up the surface preparation by 75% ensuring you have your product quicker for the next step.

Shot blasting is the process in which metal is abrasively shot at another metal surface. This is not to be confused with sandblasting, which is a similar method. However, sand is used rather than shot. Blasting is used in a wide variety of industries including, steel, forging and the aerospace industry. This is because it is often regarded as one of the most effective tools, while maintain cost effective results.

Powder Coating

In addition to being durable, powder coating is an attractive choice due to environmental advantages.

Powder coating is a high-quality finish found on thousands of products you come in contact with each day. Powder coating protects the roughest, toughest machinery as well as the household items you depend on daily. It provides a more durable finish than liquid paints can offer, while still providing an attractive finish. Powder coated products are more resistant to diminished coating quality as a result of impact, moisture, chemicals, ultraviolet light, and other extreme weather conditions. In turn, this reduces the risk of scratches, chipping, abrasions, corrosion, fading, and other wear issues.

SERVICES

SERVICES

CNC Shop

Our Machine shop has high end mills and lathes that will hit the tolerances you need. CBI offers 3 vertical mills and 1 Horizontal mill. Paired with our mills we have 3 CNC lathes and 1 manual lathe.

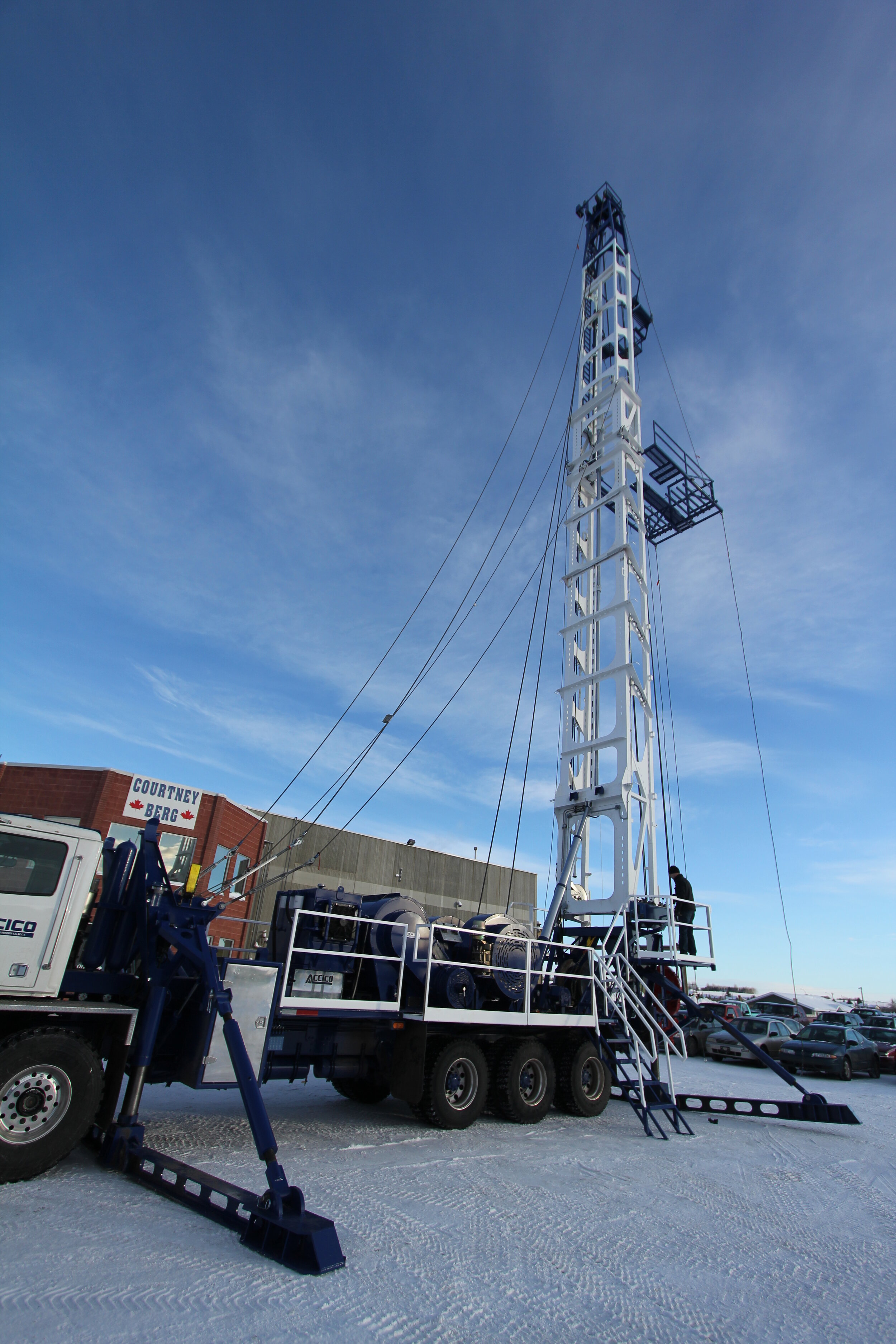

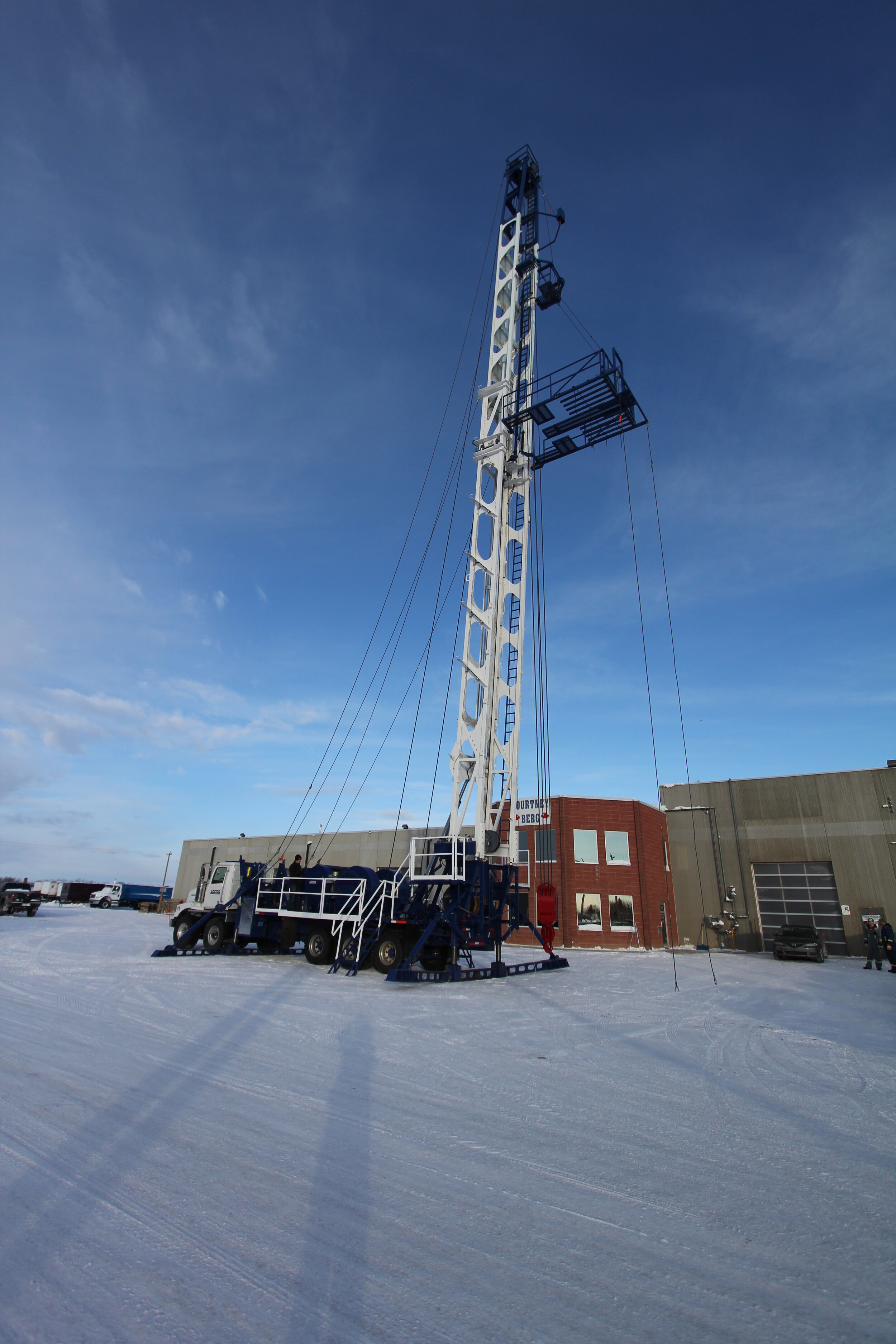

Assembly

At CBI we have experienced mechanics installing and assembling final products so you can rest assured that your product has been properly put together and installed.

CAD Drawing

Here at CBI we have Engineer techs for designing projects, so you can get your products modeled in CAD software at a low price. CBI is also a part owner in an Engineering company (Sparta) that employs professional engineers that can run calculations and stamped drawings. We have the power and knowledge to get your idea modeled the way you want it